Why our shop drawings are your plan for perfection.

Our last six posts have delved into the myriad of decisions that combine to make your custom cabinet project truly yours. Once you have successfully navigated all those decisions, it’s time to give yourself a healthy pat on the back. It’s also time for us to translate those decisions into a comprehensive set of drawings that will ultimately bring your choices to life.

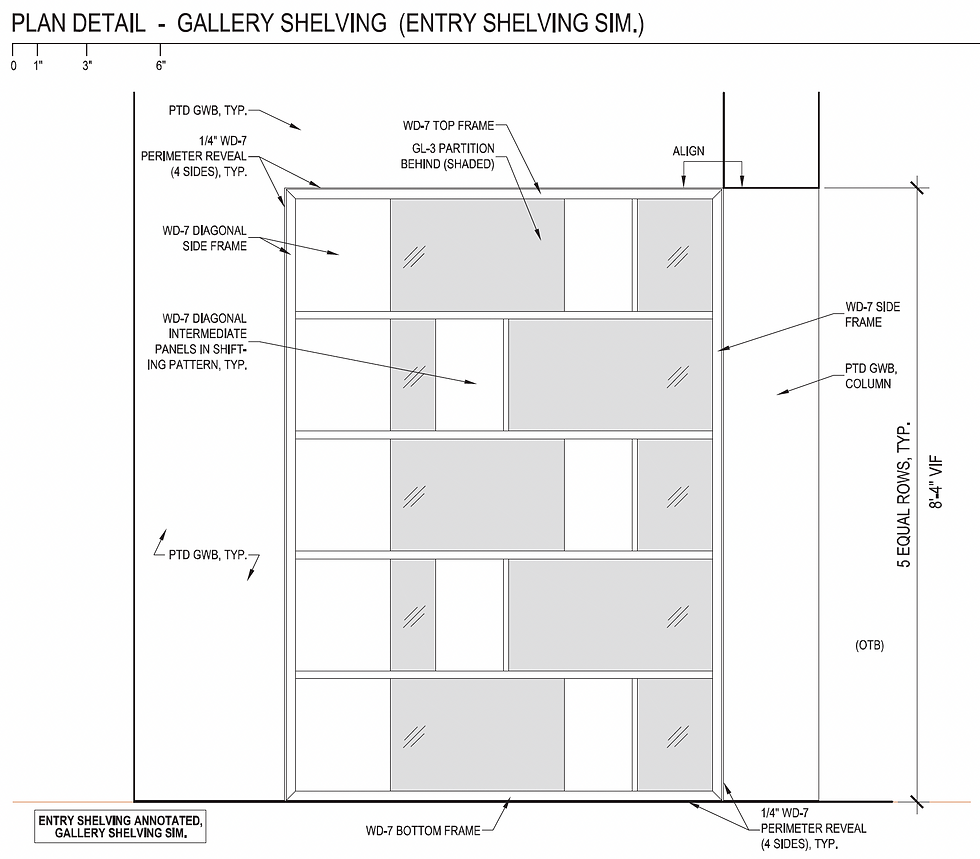

At MN Builders, we consider this stage of the custom cabinet journey the heart of the project because our drawings are tangible proof of how well we’ve listened to what you’ve asked for. They provide us with the precise guidance we need to build the cabinets to your exact specifications and ensure everything fits on-site. They provide you with a detailed look at the final build so you can understand precisely what you are getting before any shop machinery gets turned on. That’s why it is essential for all parties involved in a custom cabinet project to have drawings that are thorough, accurate, and easy to use.

Drawings defined.

In a word, what makes our drawings so unique is their thoroughness. Beyond accurate renderings, our shop drawings provide everything everyone needs to know to do their jobs, from the client signing off on the design, contractors confirming site dimensions, to the installers who assemble the final build in their home.

Our drawings include all the project details:

Finishes, door styles, hardware, and appliances.

In-depth breakdowns of plan, vertical sections, and job specific details,

A detailed timeline of milestones.

A list of all the people and roles involved in your particular project.

In essence, our drawings package comprises all the decisions we have made together and the visualizations that get everyone involved on the same page (even when that page is a digital one).

Our process.

The first step in any MN drawing procedure takes place nowhere near a drawing board. It starts on-site where we spend as much time as necessary to obtain the exact measurements to ensure that whatever we build perfectly fits the space. Once we’ve made those measurements, it’s still not time to draw; we do a kickoff with all the parties involved, including all stakeholders and subcontractors, to address any remaining questions.

Once all that prep is complete, we employ AutoCAD to create the first round of drawings. We are particularly proud of our own detailer par excellence, Kevin Braun, who has invented a system of dynamic blocks that create a plan view and all the sections at the same time while significantly reducing the number of clicks required.

Design Drawings

Time for talking.

With our first set of digital drawings in hand, the magic begins. Because we have done all that careful measuring and collaborative problem-solving, the first draft of the drawings, nine times out of ten, turns out to be pretty darn close to final. (And in fact, it better be, since the clock is ticking on our promised delivery date!)

Shop Drawings

We love the moment we first get to share all the intricate details discussed throughout the process with our client. Their eyes light up when they see all their ideas now part of a larger cohesive concept, down to the last shelf clearance and appliance placement. Although minor tweaks are always encouraged, one thing we don’t want to encourage is the shop drawing process turning into an extension of the design process, with wholesale changes to layout or scope. As mentioned, we’re in production and the clock is ticking, so make sure you’ve sorted through all of the options ahead of time to avoid added costs.

Fire up the table saws!

Once we finalize the drawings, the production phase kicks off with our decades-long investment in technology playing a pivotal role. Our shop drawings are sent to our cutlisting team, who translate them into parts lists so that the materials can be cut by our computerized saw and point-to-point router. Data from our drawings is seamlessly integrated into these machines to ensure that the cuts we make reflect the exact specs in the drawings.

Ultimately, our shop drawings aren’t just blueprints; they are visual evidence of the passion and dedication we pour into each project. Every page represents more than just design; they reflect our commitment to listening, understanding your needs, and delivering a one-of-a-kind solution tailored to perfection.

Comments